What is a Standing Seam Metal Roof?

What is a Standing Seam Metal Roof?

Choosing a new roofing to be installed for your home may be a bit daunting. There are a variety of alternatives for a new roof, and it's crucial to pick the best kind of roofing because premium roofing materials typically last for fifty years or more. If you're thinking of re-roofing your house, there are numerous reasons to think when installing standing seam roofing.

Standing seam roofs are roofing materials that are becoming more popular with homeowners. Because of its high cost, standing seam roofing is used more often for custom homes rather than tract housing developments. Metal roofing materials typically are similar in cost to other roofing materials that are premium, such as slate or tiles.

We developed this guide on standing seam roofing to assist homeowners in gaining an understanding of the material's major advantages and functions. Learn more about the reasons why this kind of metal roofing is the ideal option for your roofing.

A lot of homeowners feel that replacing their houses with asphalt shingles is right. The more discerning homeowners, however, tend to choose high-quality building materials due to their outstanding appearance and long-lasting durability.

It has become used extensively throughout the U.S. since the mid-1850s and remains among the most sought-after roofing options for commercial buildings. Everybody can envision an old barn with corrugated steel roofing panels. Metal roofing was originally constructed from corrugated iron sheets coated with zinc in order to avoid rust. Today, the primary metal could be steel, aluminum, copper, tin, zinc, and even titanium.

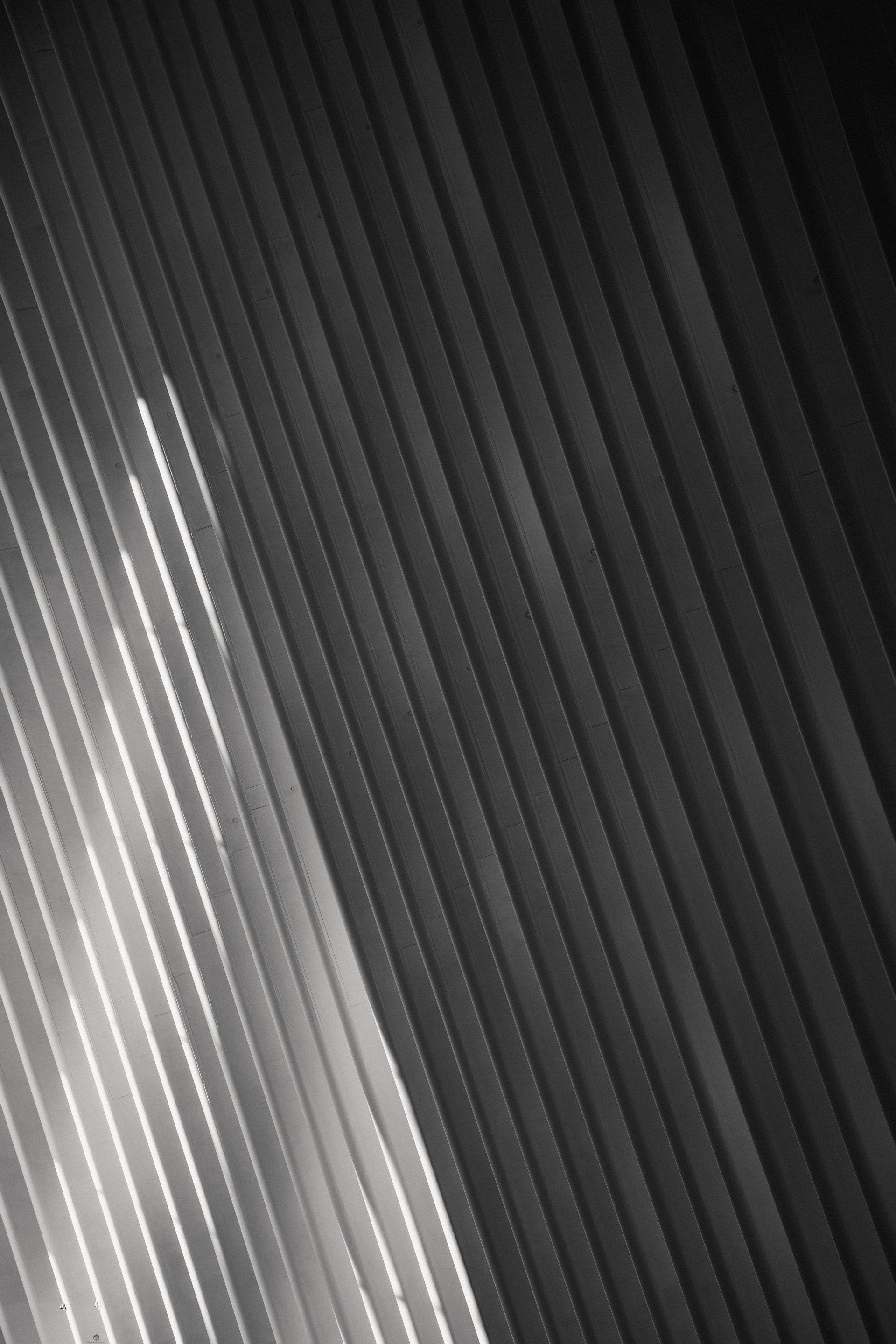

The array of styles for metal roofing rivals the diversity of base metals. But standing seam roofing is nearly all-encompassing in the world of metal roofing. It's what people consider when they think of metal roofing. Standing seam roofing is made up of flat metal panels that measure between twelve and twenty-four inches with ribs or lip, which is placed over the next panel, creating an edge that runs from the roofline all the way to the eaves.

Metal panels are made on-site or manufactured in the factory. If panels require fasteners to be incorporated into the sheathing of the roof, fasteners are concealed within the seam, creating a uniform and unbroken appearance. These kinds of panels made of steel are ideal for shorter runs because the panels are less prone, which could put stress on the fasteners and cause wear and tear. When running longer distances, the panels are made with a locking flange or clip system (slightly similar to the tongue and groove flooring) that allows these panels to "float" and avoid premature wear.

Standing seam metal roofing for residential applications usually is a little narrower in width, which is 12 inches; however, wider panels are more suitable for commercial buildings that are larger. The panels for residential roofing are typically made of galvanized (zinc) or galvalume (zinc and aluminum) steel. Steel's thickness, also known as gauge, is typically either 24 or 26 gauge for residential purposes. Steel that is as thick as 18 gauge can be used for commercial purposes, in particular when it's an element of the roof's structural integrity.

Roofing Red Deer Quote